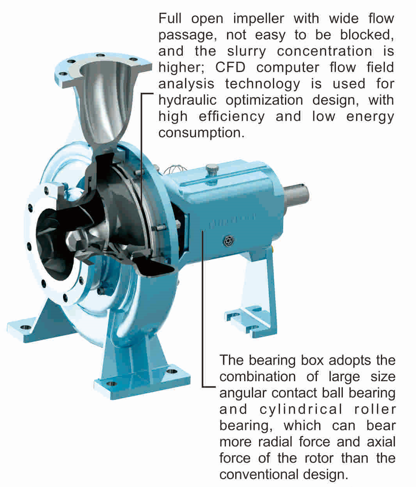

Design Feature

Full open impeller with wide flow passage, not easy to be blocked, and the slurry concentration is higher; CFD computer flow field analysis technology is used for hydraulic optimization design, with high efficiency and low energy consumption.

Single stage single suction rear door structure, supporting low vibration with the middle section of the maintenancefree long life diaphragm type coupling, pump rotor parts do not have to remove the connection flange and motor, easy maintenance.

The shaft rigidity is stronger than that of HCK type pump. The impeller is made of precision casting and CNC machine, and the dynamic balance test at G2.5 level ensures the stable and reliable operation of the pump set.

The bear ing box adopts the combination of large size angular contact ball bearing and cylindrical roller bearing, which can bear more radial force and axial force of the rotor than the conventional design, at the same time, the mounting holes of the two bearings are processed in a single clamping process to ensure the coaxial accuracy of the two bearings. which can significantly improve the interval of bearing replacement and reduce the maintenance cost.

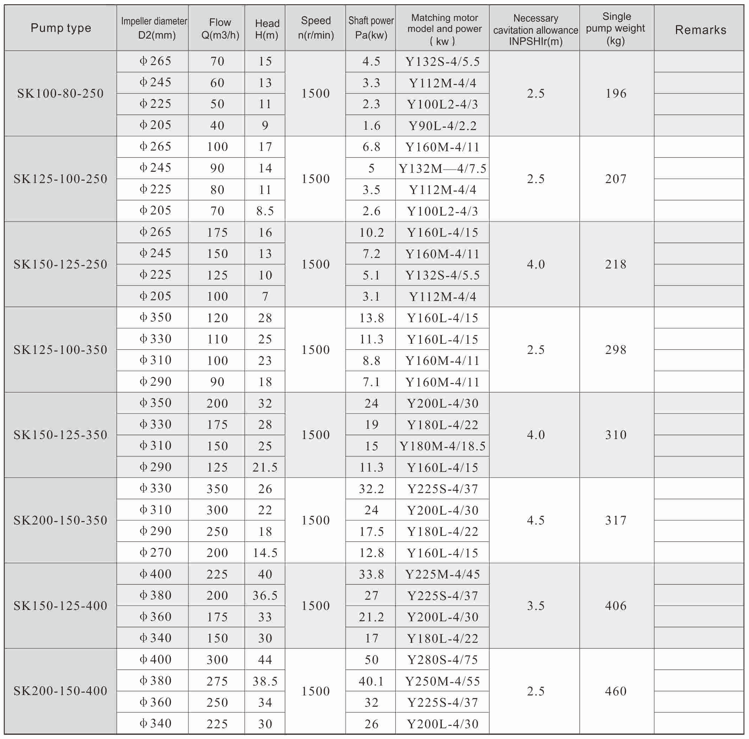

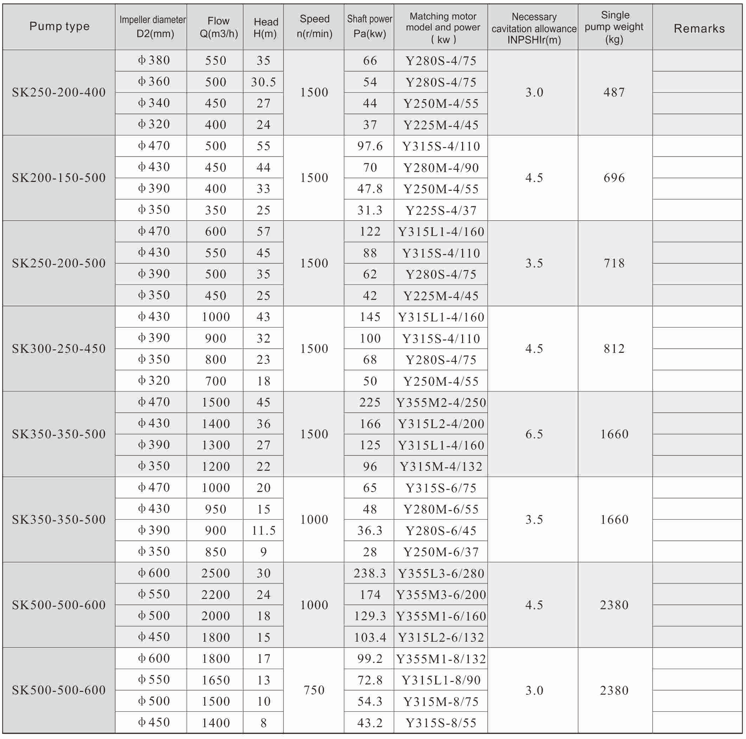

Performance parameters

Flow: 50-3000m³/h

Head:5-80m

Working temperature:≤ 150℃

Pulp concentration: ≤ 6%

SK performance parameters table

友情链接:

恒齿传动减速机